| 湿热环境苯基阻尼硅橡胶加速老化与寿命预测研究 |

| |

| 作者姓名: | 张欢 徐弘达 许文 赵云峰 |

| |

| 作者单位: | 航天材料及工艺研究所,北京 100076,中国运载火箭技术研究院,北京 100076,航天材料及工艺研究所,北京 100076,航天材料及工艺研究所,北京 100076 |

| |

| 摘 要: |

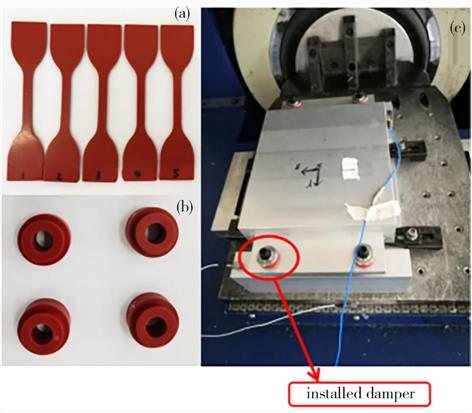

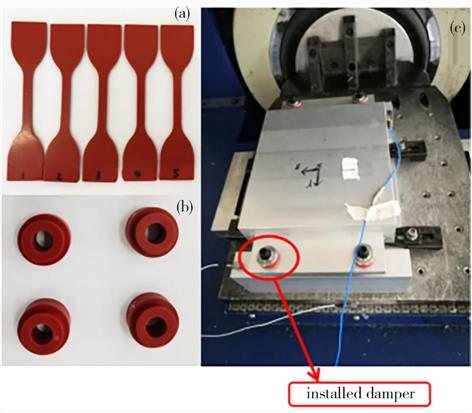

研究了苯基阻尼硅橡胶的湿热老化过程,重点考察了其拉伸性能、阻尼性能和压缩回弹性能。对于拉伸性能,实验研究表明材料拉伸模量和100%定伸应力均随着温度或者湿度的上升而逐渐提高。对于阻尼性能,损耗系数随着温度或者湿度的上升而逐渐下降。对于压缩回弹性能,压缩永久变形随着温度或者湿度的上升而逐渐上升。另外,温度对苯基硅橡胶性能的影响大于湿度。这主要归因于老化过程中同时发生了侧基氧化和水解,进而导致分子链交联和断裂同时发生。

相比于分子链断裂,分子链交联占据了主导作用。最后,采用Peck模型预测了不同温湿度环境下苯基硅橡胶的贮存寿命。由于阻尼性能决定了苯基硅橡胶的减振性能,因此将损耗系数作为评价特征参数。结果表明,在25 ℃下,当相对湿度在80%~40%间变动时,苯基硅橡胶的寿命在18~39 a间变化。此研究有助于进一步理解苯基硅橡胶的老化过程,并且提供了不同湿热环境下苯基阻尼硅橡胶寿命预测的方法。

|

| 关 键 词: | 苯基阻尼硅橡胶 损耗系数 湿热加速 寿命预测 |

| 收稿时间: | 2022-02-13 |

| 修稿时间: | 2024-04-21 |

|

| 点击此处可从《宇航材料工艺》浏览原始摘要信息 |

|

点击此处可从《宇航材料工艺》下载免费的PDF全文 |

|